Correct Use of Adjuvant Masterclass – What are Adjuvants and Their Regulatory Position

A presentation summarising the regulatory situation with adjuvants and their commercial use with plant protection products.

'Summary of the HTA Grower Technical Masterclass: ‘Correct use of adjuvants’

There is a bewildering number of adjuvants on the market for use with plant protection products (PPPs) to improve their persistence, uptake, and performance, but understanding adjuvant properties and the way they interact with PPP’s is key to getting the best from them. Very few of them have any information about their use with PPPs on ornamental crops, and guidance is often extrapolated from use on agricultural crops or other cropping situations.

As a result of the wide range of ornamental species produced commercially, an important factor impacting spray retention and uptake is the actual plant species being treated and any adaptions it may have to the climatic conditions in which it originated. Plants from arid climates, for example, may have thickened leaf cuticles, a waxy hydrophobic leaf coating, or a covering of hairs which may make droplet adhesion difficult. Some species may have a growth habit and leaf shape which assists in the rapid shedding of excess moisture, which can lead to spray run-off before any absorption has occurred.

The method of cropping also has an impact, crops grown pot-thick with a dense canopy limit spray penetration, crops grown under protection can be ‘soft’, and the growing environment can lead to rapid drying of the applied spray. The formulation of the plant protection product (PPP) may give rise to incompatibility or solubility issues. Even the water used to carry the PPPs can give rise to issues, it may be the wrong pH, too hard (in terms of carbonate content), or it may be too turbid containing high levels of organic matter which can all impact PPP performance.

An adjuvant is a supplemental substance added to a spray mixture to enhance the performance and/or physical properties of the PPP. Adjuvants cannot claim to have pesticidal activity, but they can impact product adherence to and penetration of foliage, improve product stability, solubility and compatibility, manipulate droplet size, condition the water used in the mixing process, reduce foaming during the mixing process and act as a dye to inform about spray coverage.

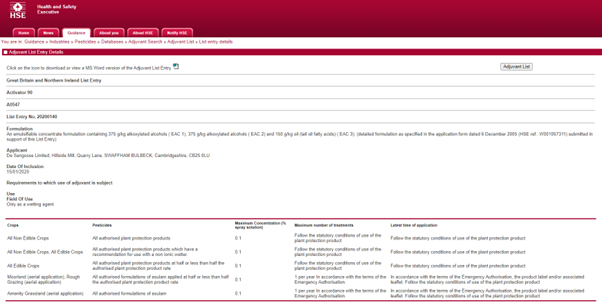

Adjuvants are not in themselves a PPP, but they are authorised under Regulation (EC) 1107/2009 The Placing of Plant Protection Products on the Market and are also subject to (EC) 1272/2008 The regulation covering The Classification, Labelling and Packaging of Substances and Mixtures. More information about the regulations and access to the official list of adjuvants can be found on the HSE website. Within the database information can be viewed on crop use, the PPPs the adjuvant can be used with, the maximum concentration, maximum number of treatments and latest time of application of the adjuvant.

Adjuvants can be broadly divided into two groups – 'activator' which enhance the biological activity of the PPP and 'utility' which alter the physical characteristics of the spray solution to maximise performance. Key substances in the first category include surfactants and oils which impact the spray droplet on the leaf surface and its passage into the leaf. A broad number of substances fall into the second category including stickers, drift retardants, compatibility agents, conditioning agents, water conditioners, acidifiers and buffers, colourants, anti-foaming agents, humefactants, markers and tank cleaners. Many products have multi-purpose activities and can be used for a range of roles, e.g. spreader/sticker/wetter.

The six basic steps for selecting the correct adjuvant are reproduced below:

Always test a small area first before using a PPP–adjuvant mix on a commercial scale. Using an adjuvant at a lower concentration reduces the risk of potential crop damage. Single purpose adjuvants tend to be safer to crops than multi-purpose ones.

Insecticides

Most insecticides are liquid formulations, but there several solid formulations. Most have a contact mode of action, with a requirement to be fast acting and efficacious. Some can be damaging to crops at different growth stages. Non-ionic surfactants e.g. Activator 90 – used to improve the performance and uptake of insecticides during the main season when soft growth is present. Spreaders e.g. Silwet L-77 – help to reduce the surface tension within droplets and improve uptake. Stickers e.g. Bond – improve the retention of PPPs. Oils e.g. Codacide – mainly used in the autumn and winter with contact acting insecticides, can carry a phytotoxicity risk and leave an oily deposit. Water conditioners e.g. X-Change – used to adjust water parameters to meet the specific needs of the insecticide.

Fungicides

A mix of solid and liquid formulations. Many fungicides do not require adjuvants, especially liquid formulations, but they can assist contact-acting fungicides. There can be tank mixture issues with fungicides. Non-ionic surfactants e.g. Activator 90 – used to improve the performance and uptake of contact-acting fungicides. Spreaders e.g. Silwet L-77 – help to reduce the surface tension within droplets and improve uptake. Penetrants e.g. LI-700 – help to improve uptake. Stickers e.g. Spraygard – used to improve spray retention.

Herbicides

Generally liquid formulations. Where volatile active substances are used, stickers can reduce volatility and crop damage. Pre-emergence herbicides used on seed beds can also benefit from a sticker. Total weed control products should always be used with an adjuvant. Water conditioners and spraying aids – stickers, acidifiers, markers and drift reducers are sometimes used, oil-based adjuvants tend to be used mostly as enhancers. Spreaders e.g. Silwet L-77 – help to reduce the surface tension within droplets and improve uptake. Stickers e.g. Spraygard – used to improve spray retention. Oils e.g. Codacide – used to enhance contact herbicide performance.

Plant growth regulators (PGRs)

Generally liquid formulations, with one exception. Many are formulated with the appropriate adjuvant. Avoid using silicon-based adjuvants and oil formulations due to the phytotoxicity risk. Non-ionic surfactants e.g. Activator 90 – used to improve the performance and uptake of the PGR. Penetrants e.g. Elasto 5G – help to improve uptake.